Hello everyone,

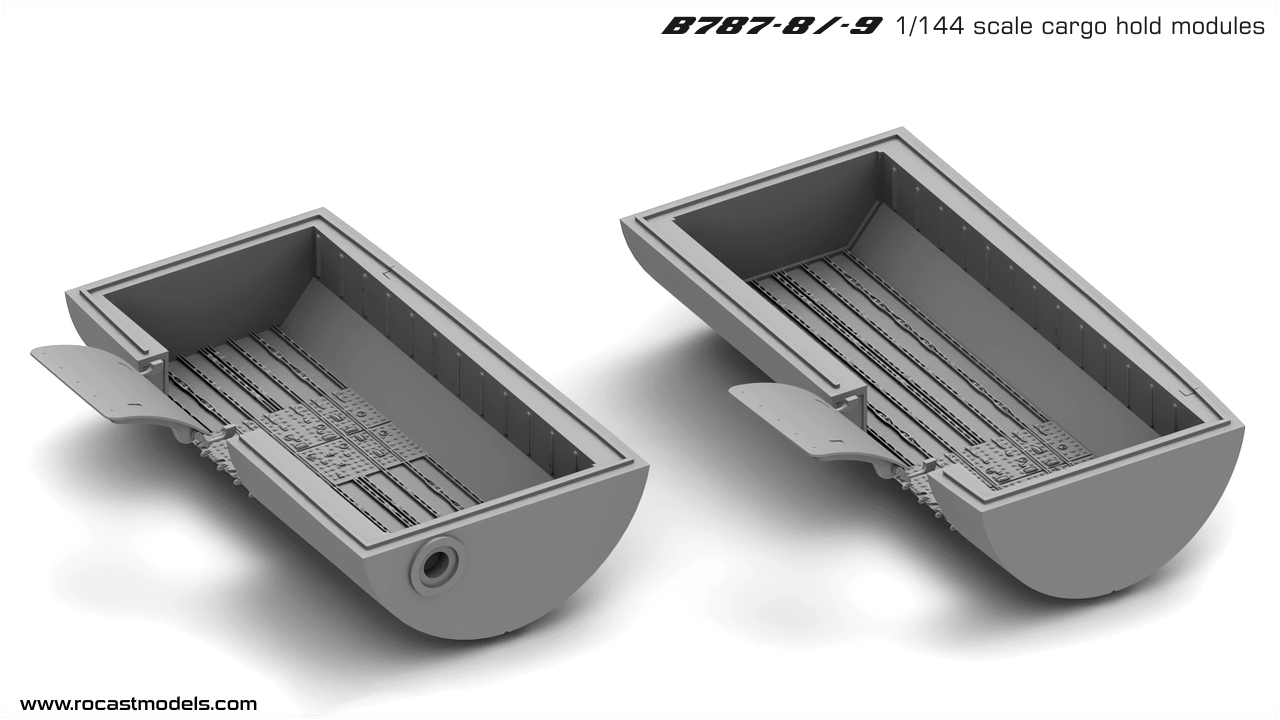

Just a very quick update today to share the completed design of the B787 cargo holds.

As you know, I had some issues with the production of these, especially for the forward cargo hold, I have re modeled the basic shape so that it would be easier/quicker/better for me to produce, so this new design will allow me to have a more efficient restock.

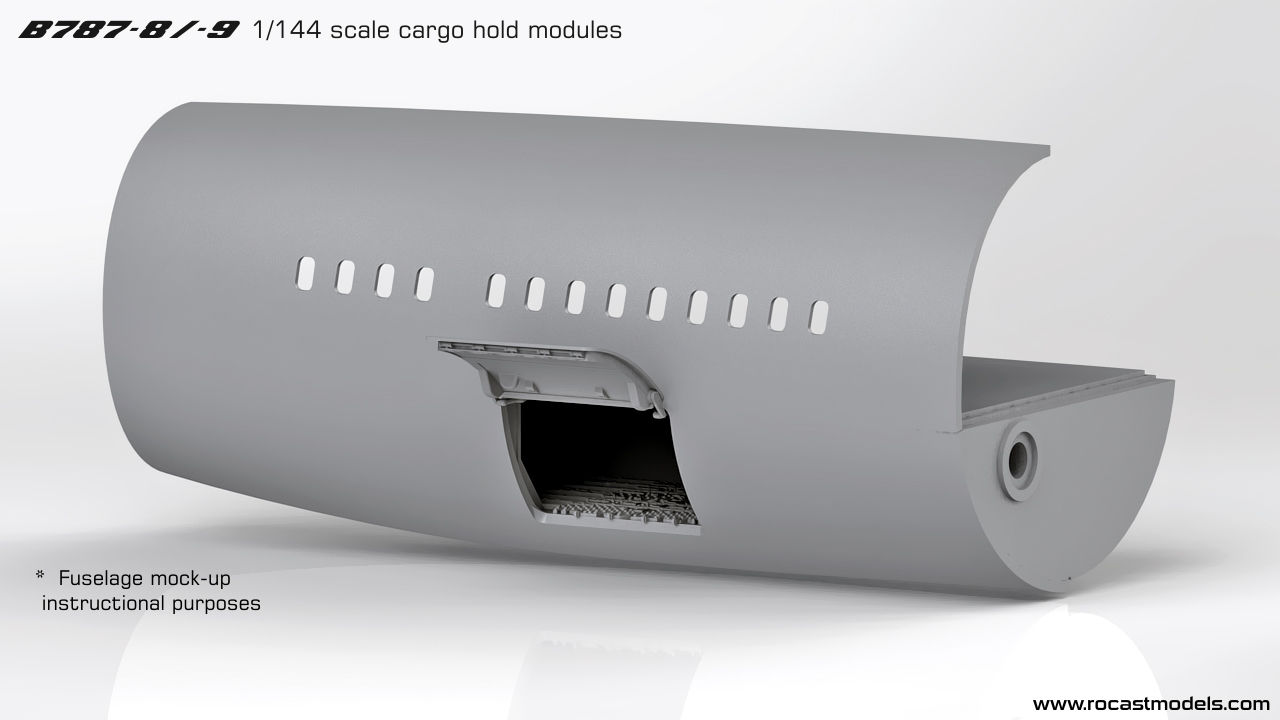

There is one important difference from the previous version, this new one will work with both, the -8 and -9, covering both Revell and Zvezda manufacturers.

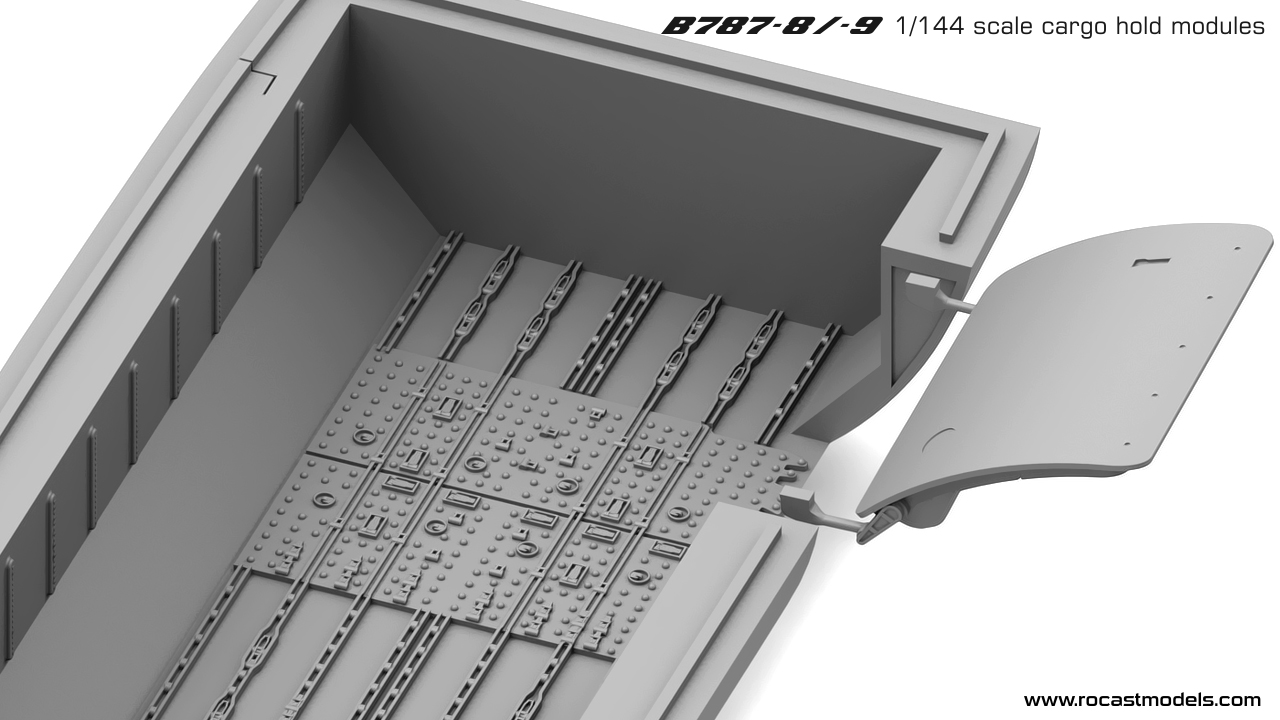

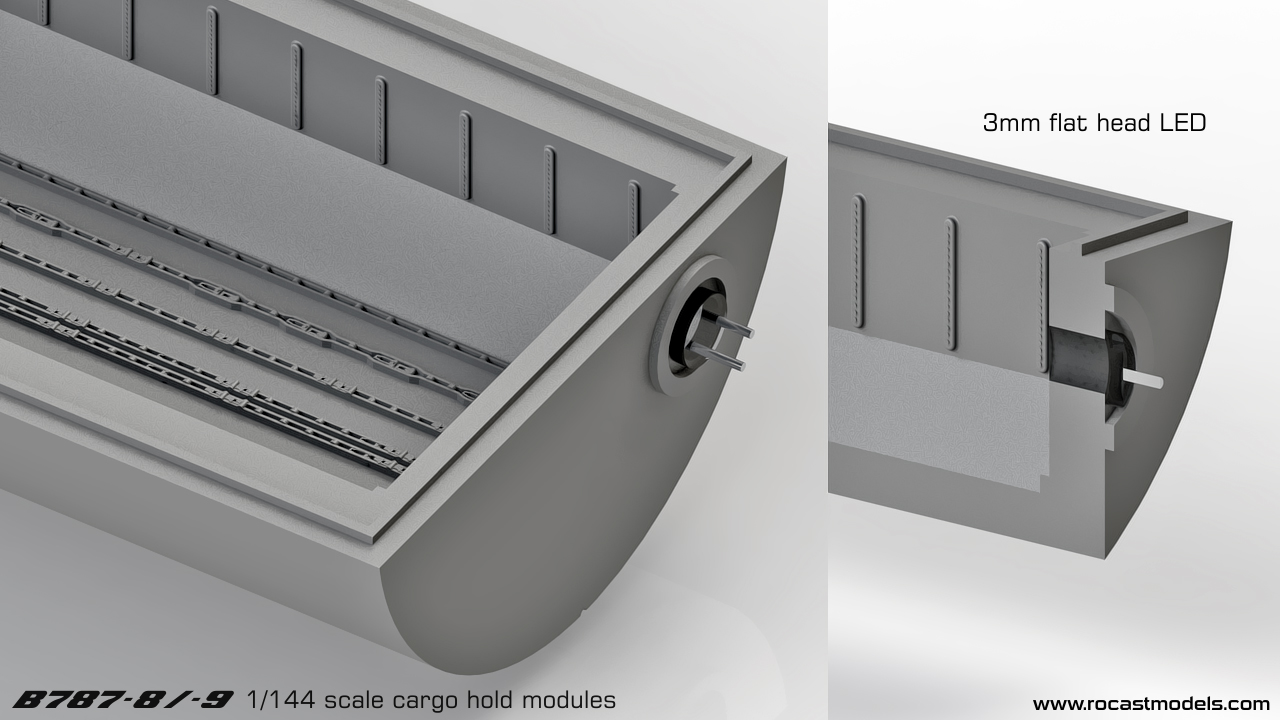

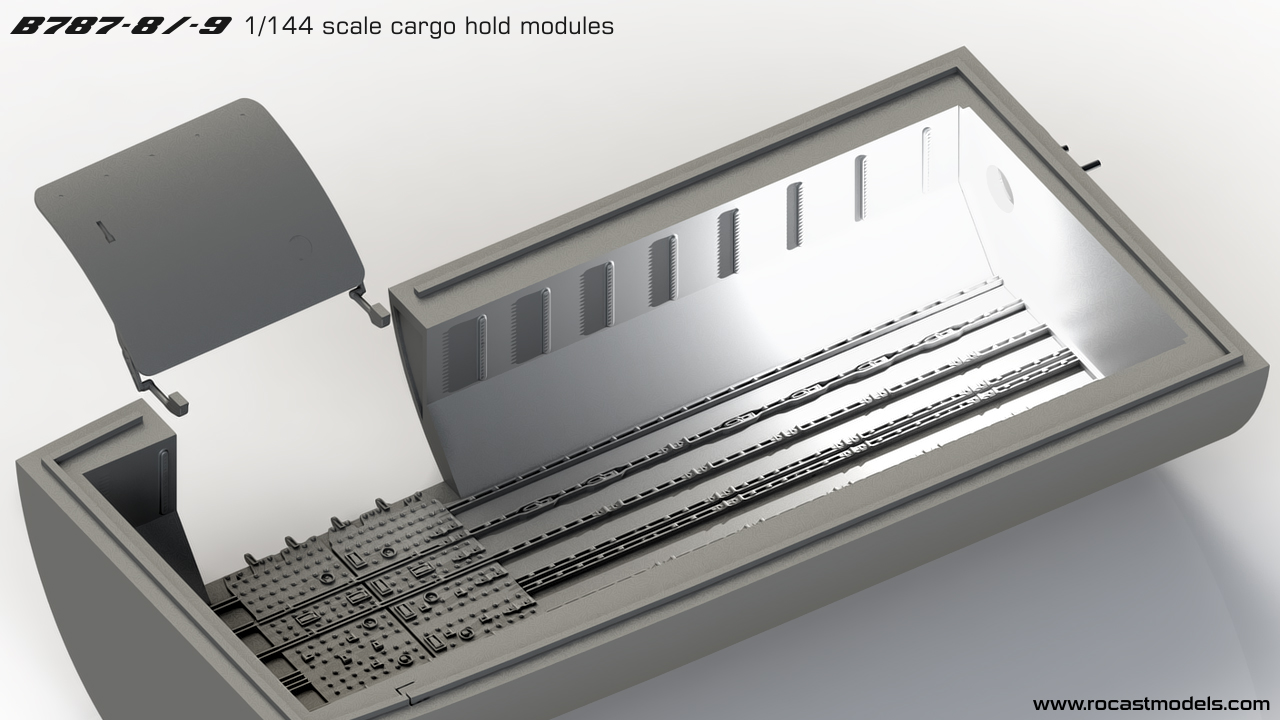

There has been a prepared spot for a 3mm flat head type LED. As wires can be a bit limited to pass outside the model, instead of using several micro SMD leds with lots of wires, using a single LED for ambient lighting is a “cleaner” approach. I am not sure whether I should include the option with and without LED, these type of LED usually don’t have a soldered resistor from factory, so I may provide this option in case you would like light inside but don’t have a soldering iron, the LED would be tested and prepared with a resistor, leaving the LED ready to be glued in place.

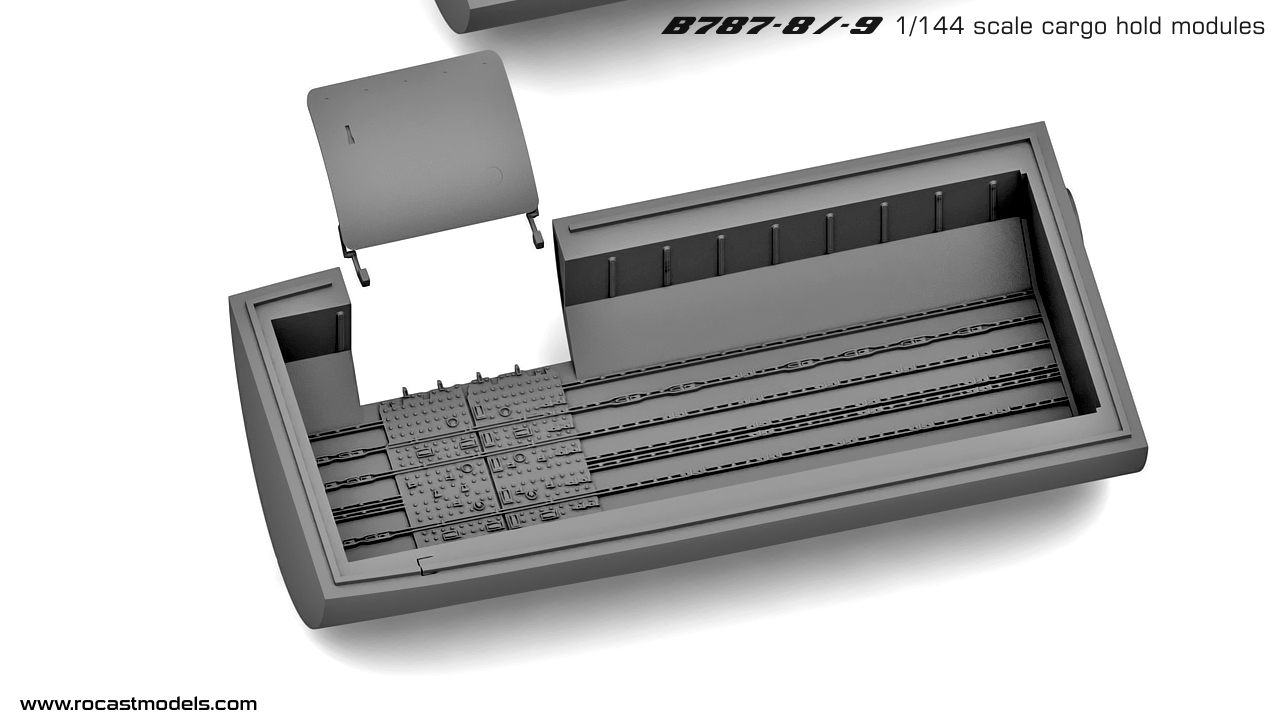

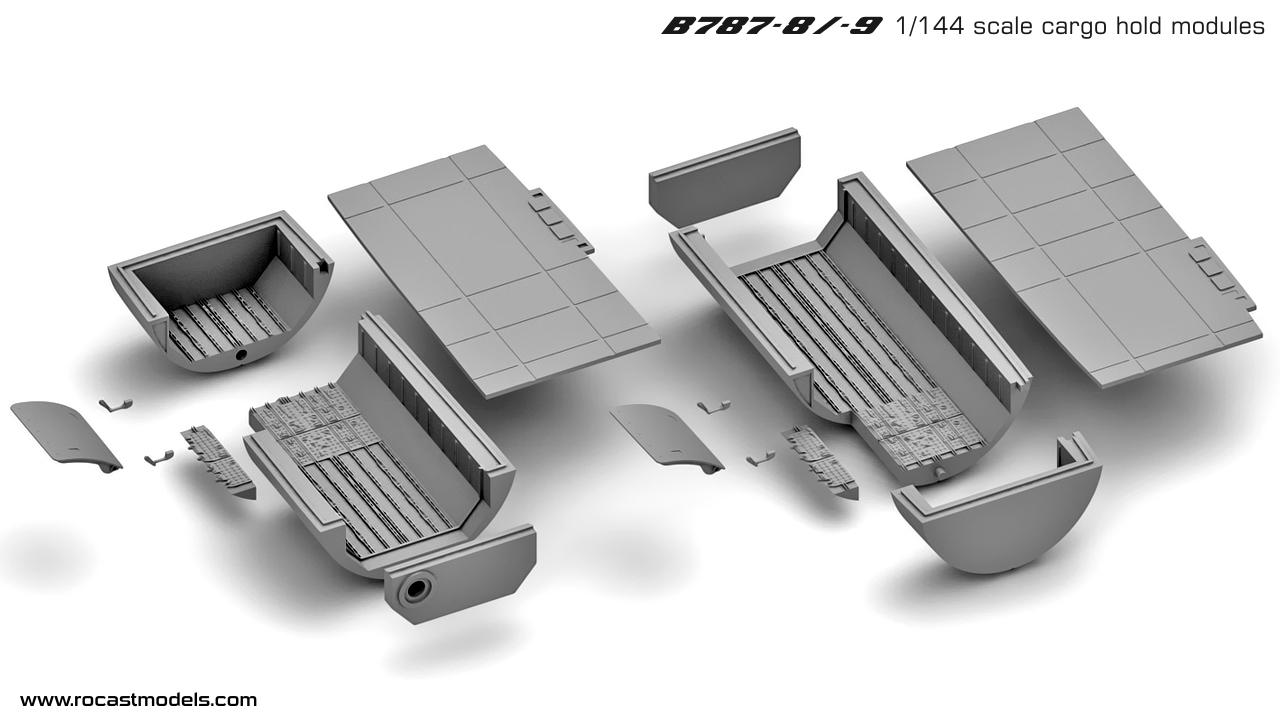

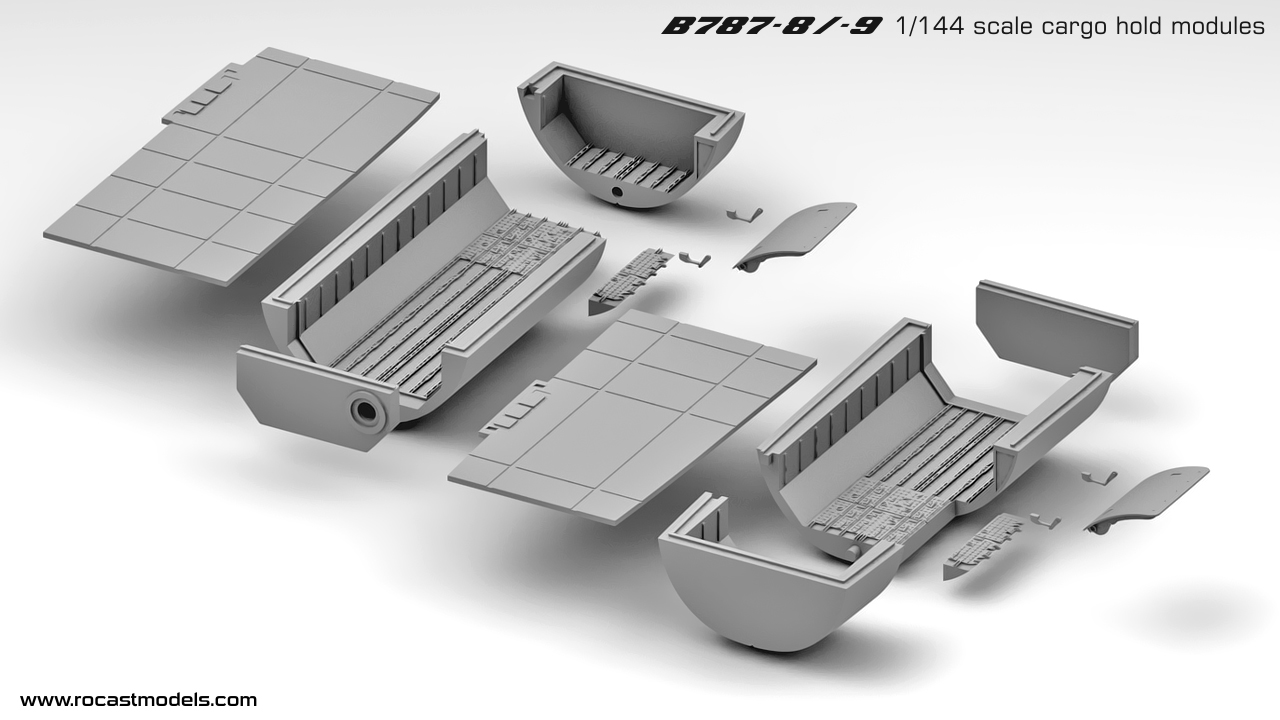

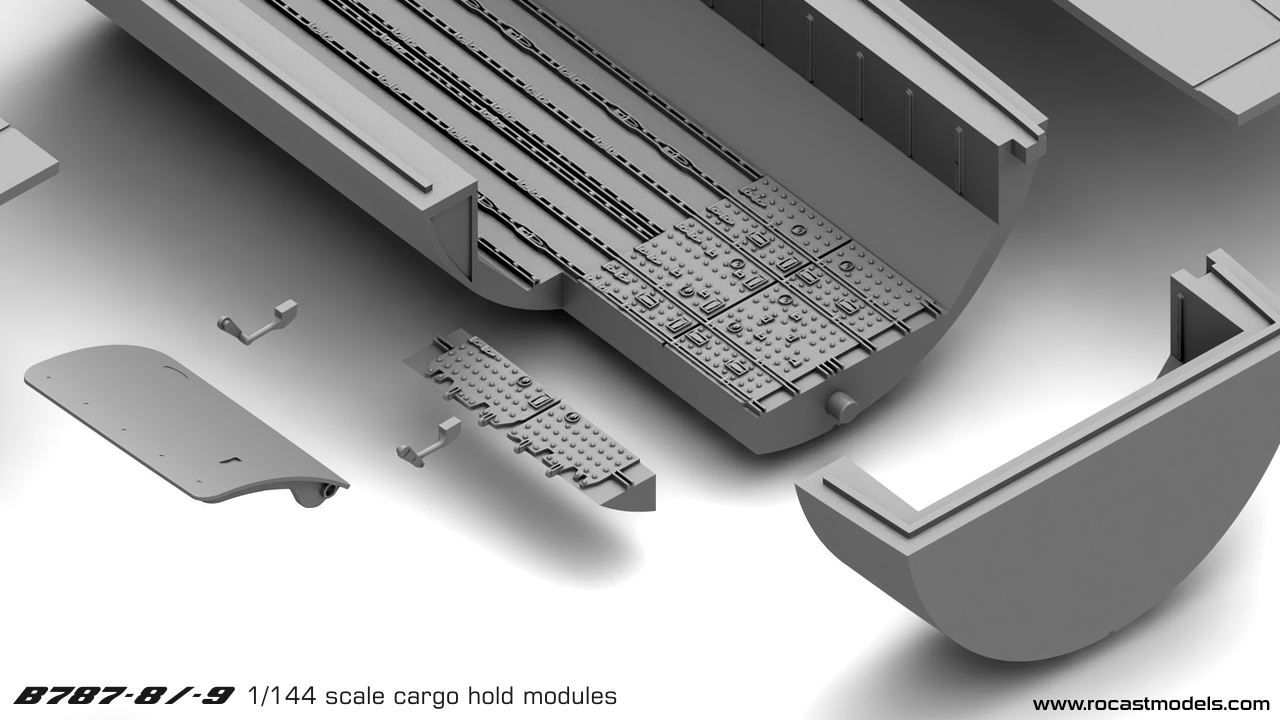

In the image above and below you can see the exploded view of the included parts.

Parts were designed this way for both, an easier production process as well as an easier assembly.

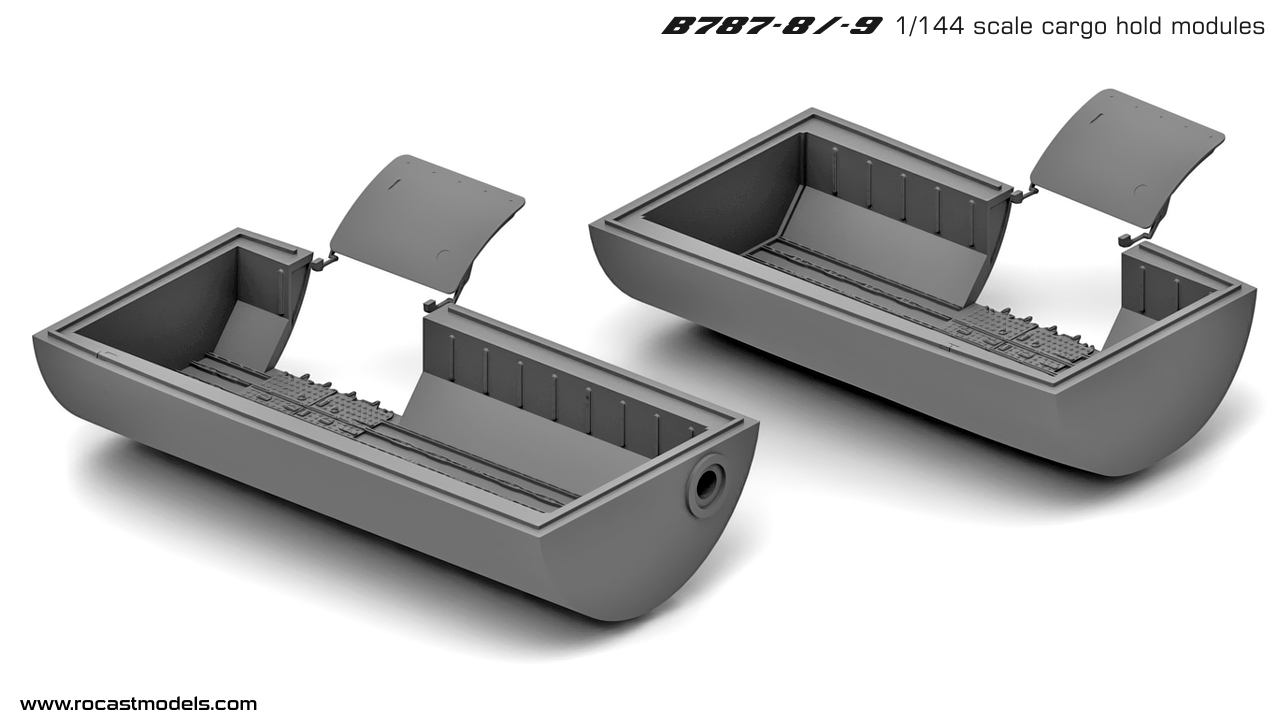

The 3mm LED will fit in place, just for its flat head to show at the back wall and illuminate the interior. This is a very similar approach as to my B747 cargo project, where LEDs are located at the opposite corner of the door opening, away from the eyesight.

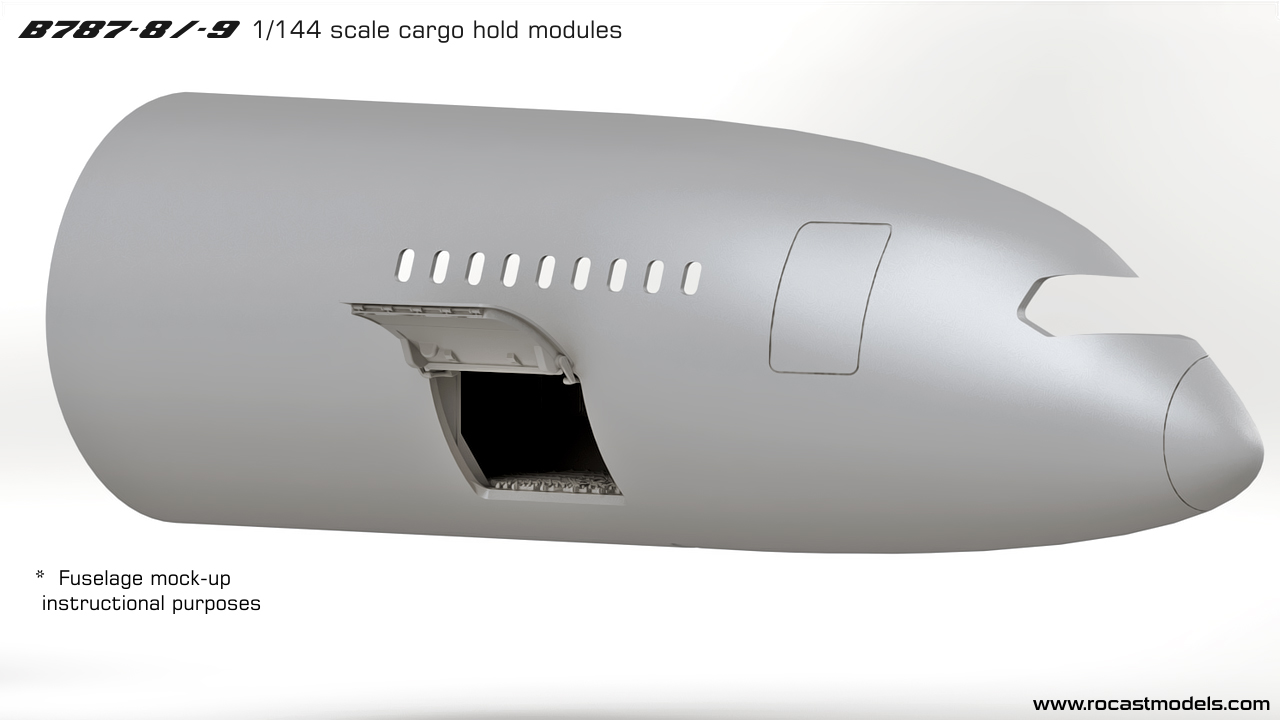

A fuselage “mock-up” or dummy was done for two reasons, 1; to see the adjustment and fitting with the kit’s plastic thickness and 2; for instruction purpose.

The latches at the edge of the fuselage will be the same as the original ones in the previous version, being left aside in the previous renders.

A test was already done with both the forward and rear cargo holds, they both fit the fuselages of the -8 and the -9 kits. As much as I wanted to present a finished real version, I cannot do so until I can have my new printer to do it as best as possible. As you know, my recent purchase did not go so well, so it had to be returned and I am awaiting for restocking.

Therefore, I have to wait to print the master parts, at least till the end of March, so these cargo holds are also on the list together with the B747 cargo parts to print.

Before finishing this post, another thing to mention on the B787, I may make a similar remodel for the galleys, the forward galley/cockpit module is also a complex part to produce that always requires me extra time that can be easily omitted if for a better layout design at production time. The center galley module needs to be checked for fitting with the newer version of the cargo holds.

I am at a point where I shouldn’t be producing three cockpit sets of one single model in one hour if I want to grow the business, especially knowing that I can speed up production without losing detail, it is not all about 3D printing, since I also resin cast. There are limitations on what can be done faster/slower, but keeping detail (increasing it in the future)+ higher quantities per hour is the optimal process.

After finishing this work on the B787 cargo holds, I am having in mind another airliner, so hopefully I can create more parts in the future.

This weekend I am finally starting with the process of the 1/200 towbar pushback models, the F110 and F210, so I hope to share more about this in the next update.

Last but not least, an adjustment to the B747-8F panel lines at the hump was done.

This is all for now, work continues.

Wish you all a very nice weekend!

Guillem