Dear all,

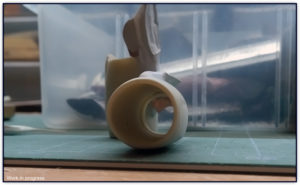

I have finally completed the two pylons for the 1/144 LEAP-1A engines.

I have used a number of photos and created a 2D diagram to make sure that the pylons have the shape of the real aircraft’s pylons. They fit to the wings nicely thanks to the putty that took the shape of the wing and particularly of the leading edge.

I have also accentuated a little bit more the hump by adding a 0,3mm plastic rod and putty around it.

The next steps that need to be done are:

- Create the exhaust.

- Adjust the lower lip/diffuser.

- Mark the inner ring line.

- Decals (so far I made the marking decals, but I want to pay special attention to the pylon decals).

- Creation of the Photoetched parts.

I also need to sand a little bit more the pylon to remove some scratches and tiny holes of the putty.

Once the three steps above have been done, I will proceed to the first resin casting.

My goal was to release it this week together with the new A350 sharklets/decals, but I may not be able just yet since I also have to design the instructions for the engine, although I think it won’t take me much time.

LEAP-1A are definitely going through the final stage, the most critical points have been completed and I expect to have the first units during the next couple weeks.

The 747-8F/-400F deck and B737 cockpit have been on pause because of the work with the LEAP and the A350 sharklets.

Once the LEAP-1A and the A350 sharklets are released, I will resume the cargo deck set and the 1/12 cockpit.

In the meantime I have been working on some new A320Neo liveries, the two recent ones are the Frontier N301FR (Wilbur the Whitetail) and N308FR (Flo the Flamingo). Will defenitely be working on more Frontier liveries and try to make some other LEAP-1A aircraft liveries since there is a little bit of limit with the PW Neo liveries.

I am also excited to mention that thanks to my friend Michael I’ve got more measurements for the FMC15i cargo loader and I am currently designing what will be the project that I will start once I finish these engines.

I have been studying the different elements of the cargo loader and after the experience I gathered from the previous one, I expect to make this one more detailed and realistic. Initially there will be a higher number of parts, specially more photo etched parts than the previous version.

Sometime whithin the next two weeks I will update again the blog on news about these projects and with the LEAP-1A release together with new livery decals. I need to have the first unit made to make the pylon decals, so my goal is complete the steps mentioned above and have the mold made during this week.

Best wishes,

Guillem