Hello everyone,

It has been quite a while since my last update, the one I am bringing today will have lots of information which I hope you will find interesting.

I want to start apologizing for not having progressed as much as desired with the 787 project. As you may know, I am not exclusively working only on this, but I also require of the time to process orders, restock products, respond customers as well as redesign “old” items that have been on demand lately (more below) and keep on preparing new articles that don’t require as much time as the 787 but that are also very much helpful to keep things going.

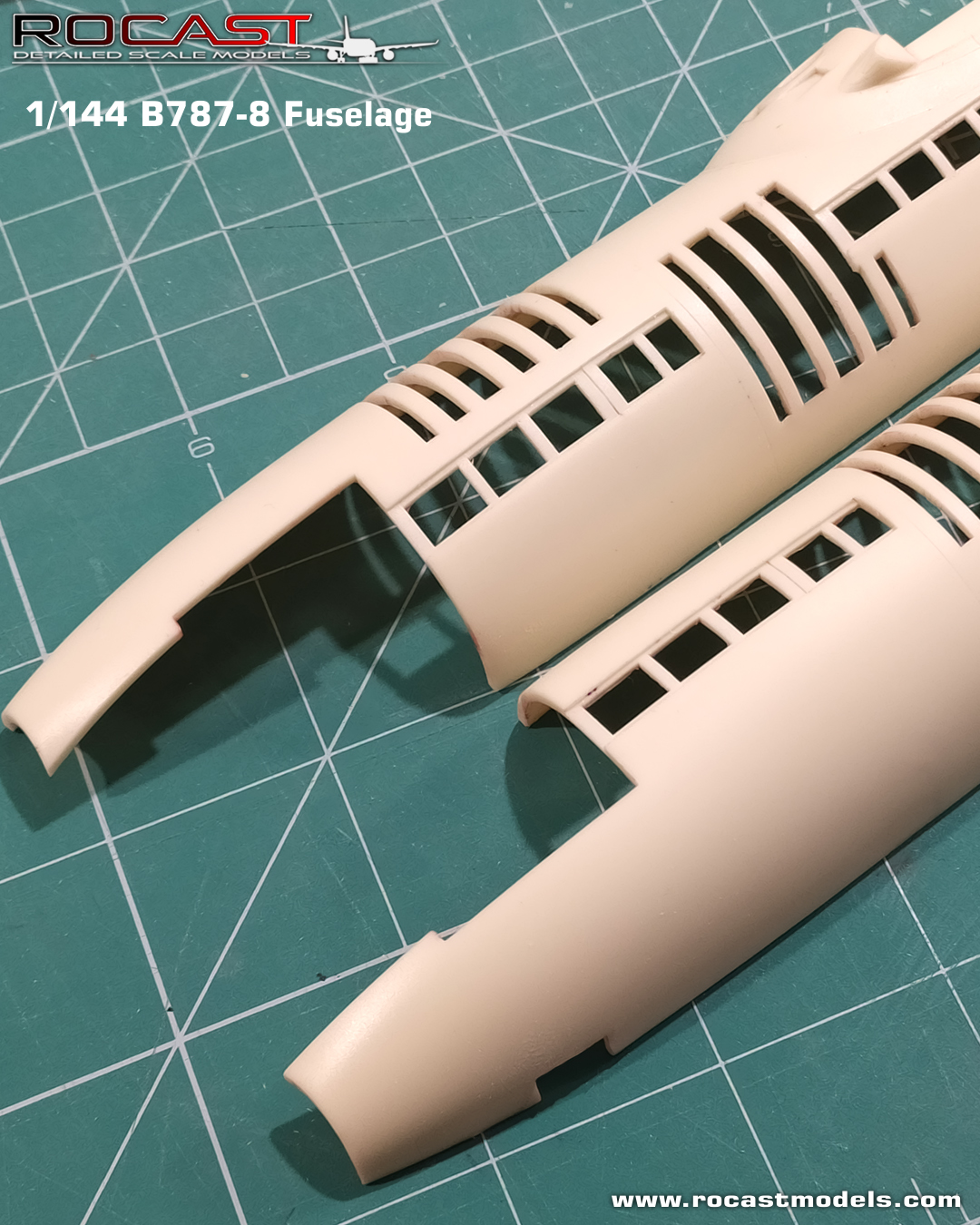

The mold for the 787-8 fuselage was done, however, the silicone I used was not the most appropriate for the task, you may not know this but there are actually quite a wide range of silicone types, so I was trying to use the best I could find based on the past experiences.

Nevertheless, as the images will show below, the first cast came out nicely, there is no problem making the molds in such way, which in itself is already a success despite the delay for the release of the project which is not caused by me being stuck at some point, but simply due the workload that I have at the moment.

The grey model was the master and the beige, the resin cast:

I am taking the chance to renew most of the 787 molds by using a longer lasting silicone, it is quite a consuming task to do, but that in itself does not present major issues.

I am also planning on releasing this new 787 set with silk screened window frame decals, which is already a challenge in itself because I plan to make them myself. The project is progressing slowly (apologies) but steady, there will be further progress to share soon as I am finishing other minor tasks.

This leads me to the next update; the transparent cabins for the GSE vehicles (as well as the 787 passenger windows).

After several months I found what works best for me to achieve the full clear/gloss/smooth transparent windshields, it has been countless trials and errors, changes in materials and tests where I kept resin pieces under the Spanish sun for a few months to later discover they did not yellow at all keeping perfectly their appearance and transparency.

Had to change the molding techniques several times to adapt to the new resin I am using which also required some time to understand, you can see in the image below the Volvo FL Electric cabin in the three scales, 1/72, 1/144 and 1/200. This is how I plan to design all the new and updated GSE models, transparent cabins instead of acetate windshields, kits will include their corresponding painting masks.

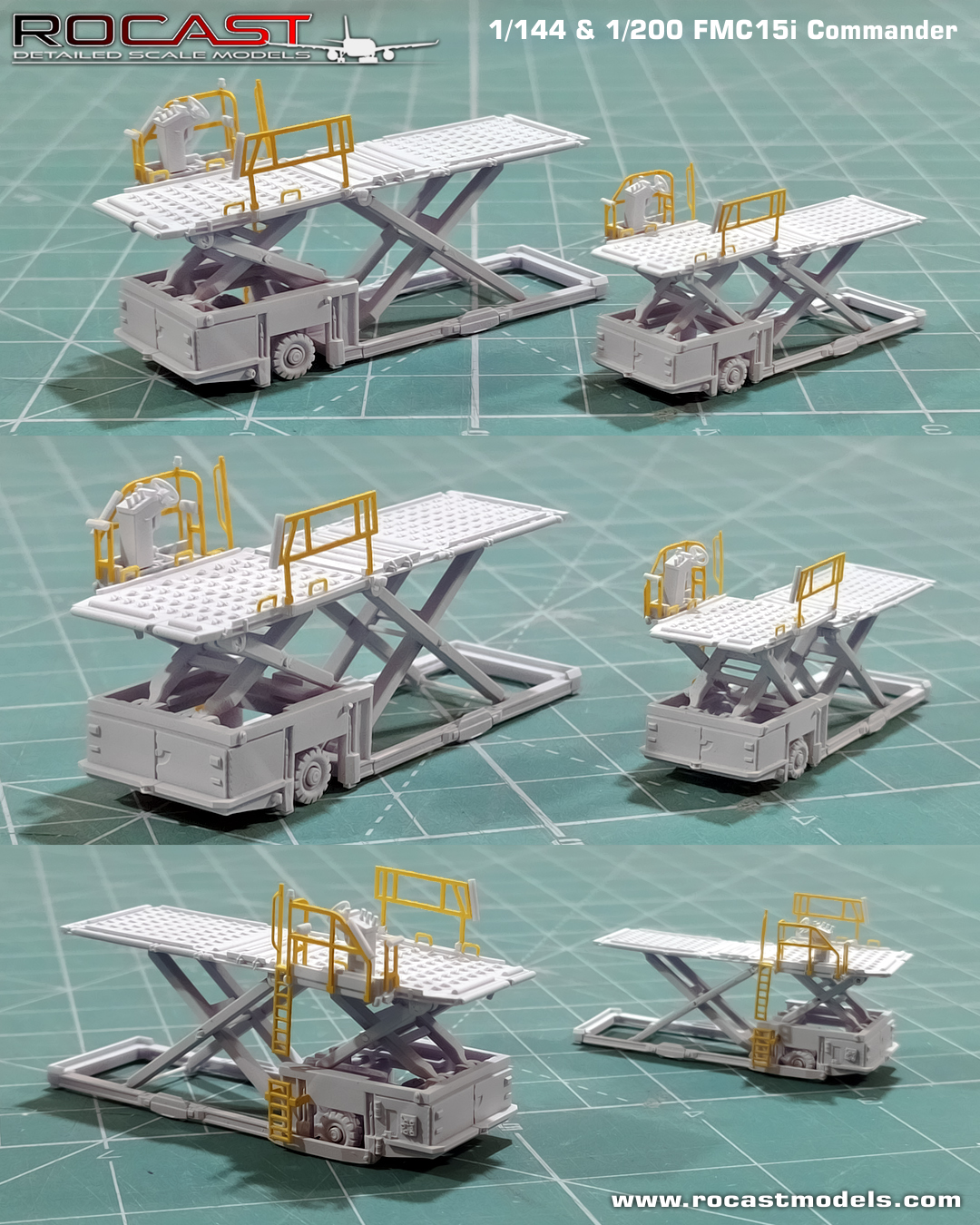

As I mentioned in my earlier entry, the FMC15i Commander cargo loader will be reissued, this will come at perfect timing for the 787 and those who want to have the cargo holds opened.

I have been realigning some parts of this model kit for a better printing as well as using it as a test bed for me to finally say goodbye to the photo etched parts.

Making photo etched parts required the handling of chemical materials that were not so great to handle on a regular basis, the process was a bit long, expensive and toxic, I also felt that I could not only depend on a single material manufacturer (despite having done so many tests with other brands in the past).

As the images show below, I was able to push the printer to print the handrails only 0,25mm thin in the 1/200 variant, which was already the thickness I was having for those PE handrails on the cargo loader. Removing the supports from those thin parts is not as difficult as you may think since the handrails retain some flexibility, I was also able to readjust the thickness of the printing support tips, so now removing supports from the 3D printed parts will be much easier and I will be renewing this as I make stock for the various articles. The loader will include two parts of each handrail/ladder as a backup part.

To me personally, these handrails (all the parts in yellow, which used to be photo etched parts), are now better respresented, they have a bit of volume and this will also allow me to make lots of other details this way as well as creating ladders which is something I also plan for the future.

The 1/200 version of the cargo loader is nearly as long as an AAA / LR03 1,5v cell. Both cargo loaders can have their platforms and bridges adjustable.

Not only these changes were done to the cargo loader, but also the stairs truck model “rod and tube” were redesigned and 3D printed. As several of the “old” GSE are out of stock at the moment, the new stock for the stairs truck will come with these new rod-tube parts.

Both models were downscaled to 1/200 retaining the detail that can be seen in the 1/144 models, so it is very possible that both, the FMC15i and the TLD ABS1740 models will be included in the 1/200 catalog as well.

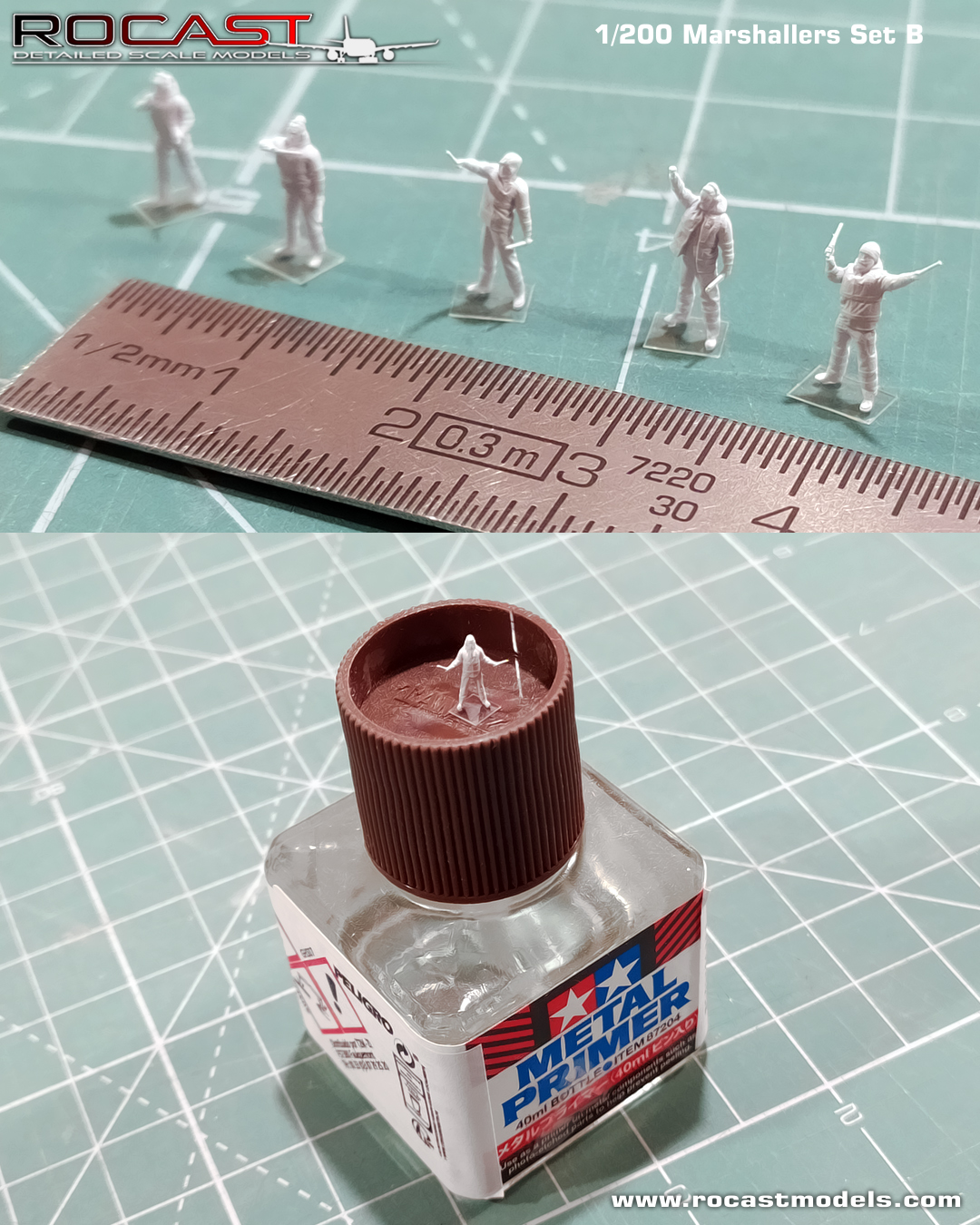

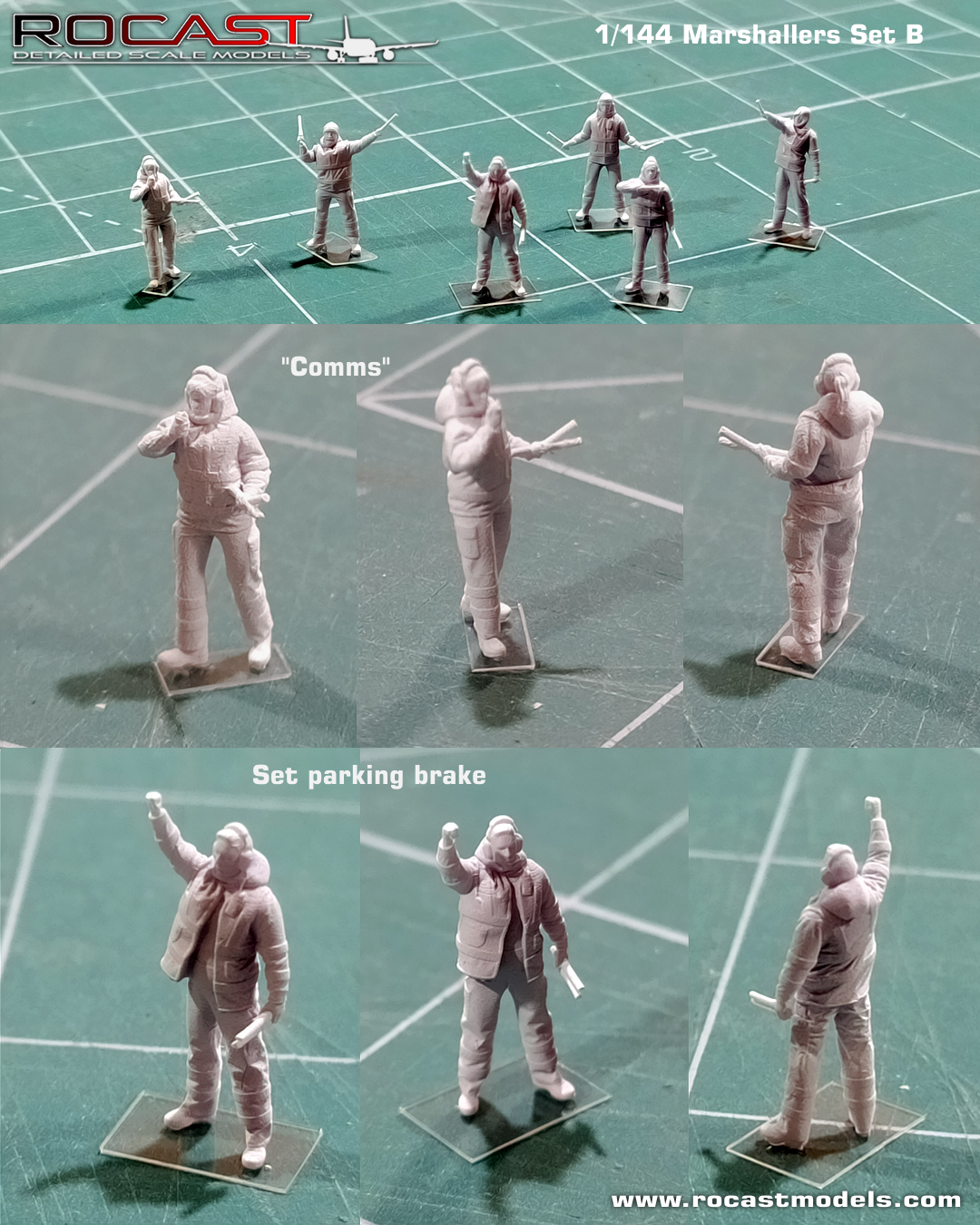

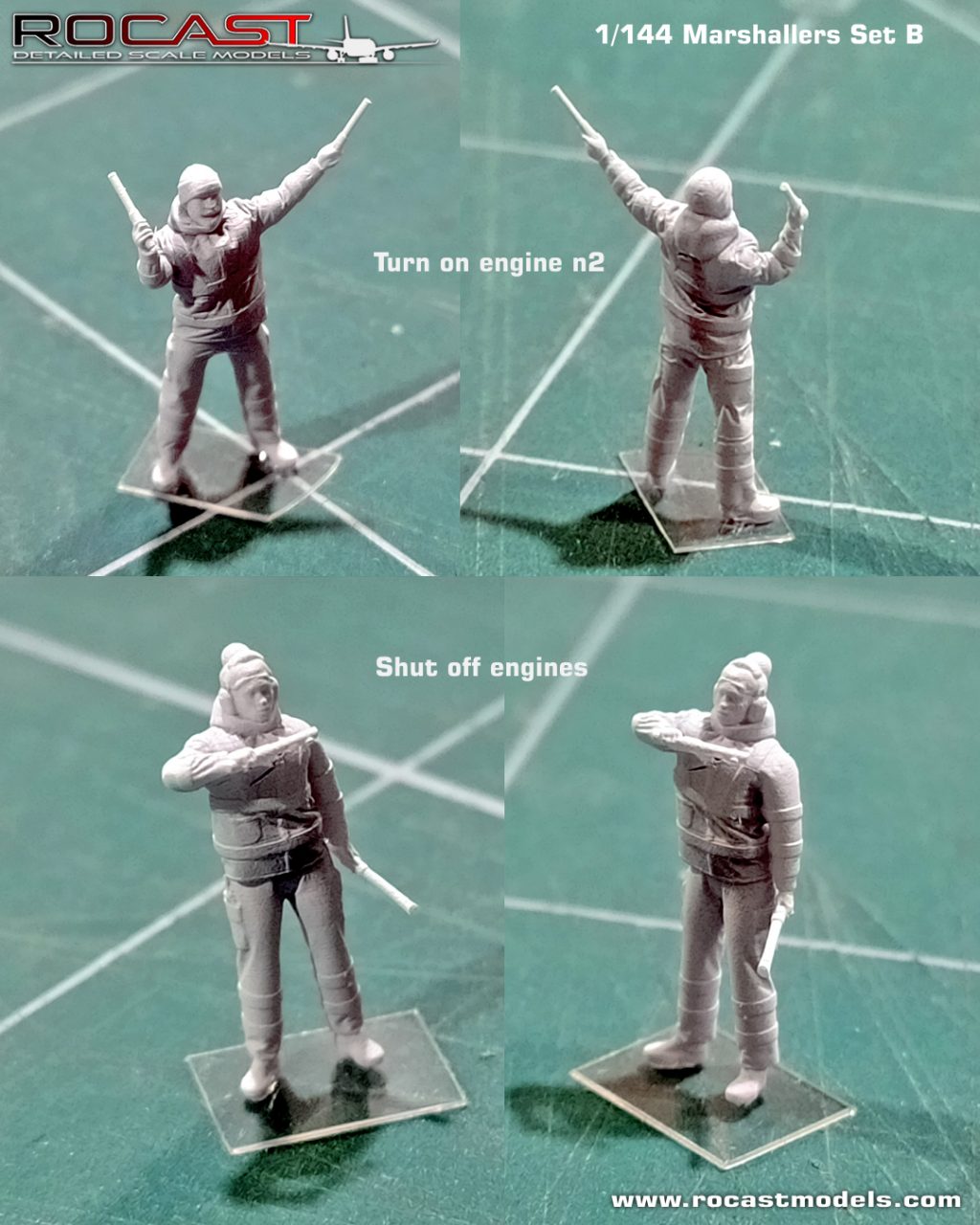

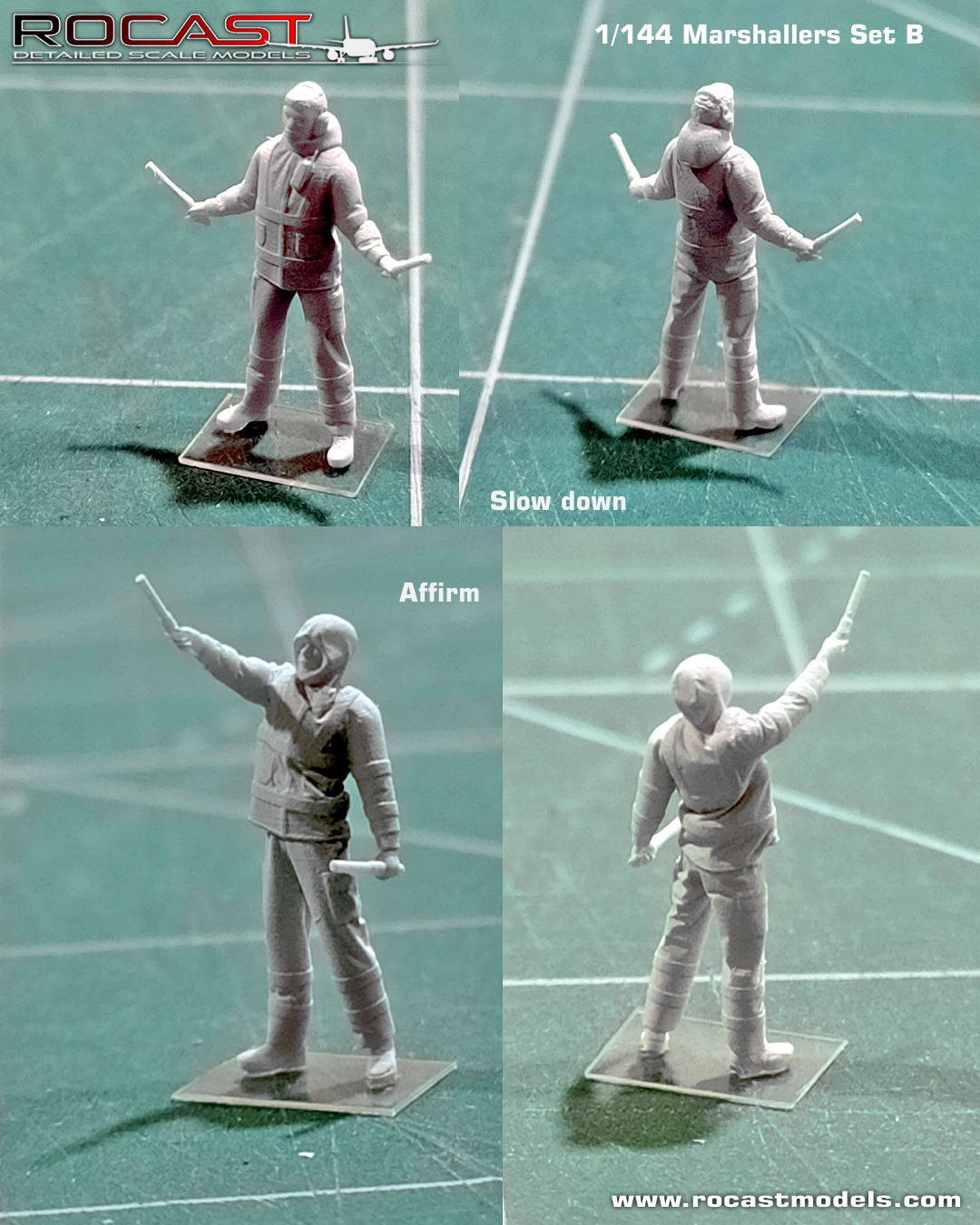

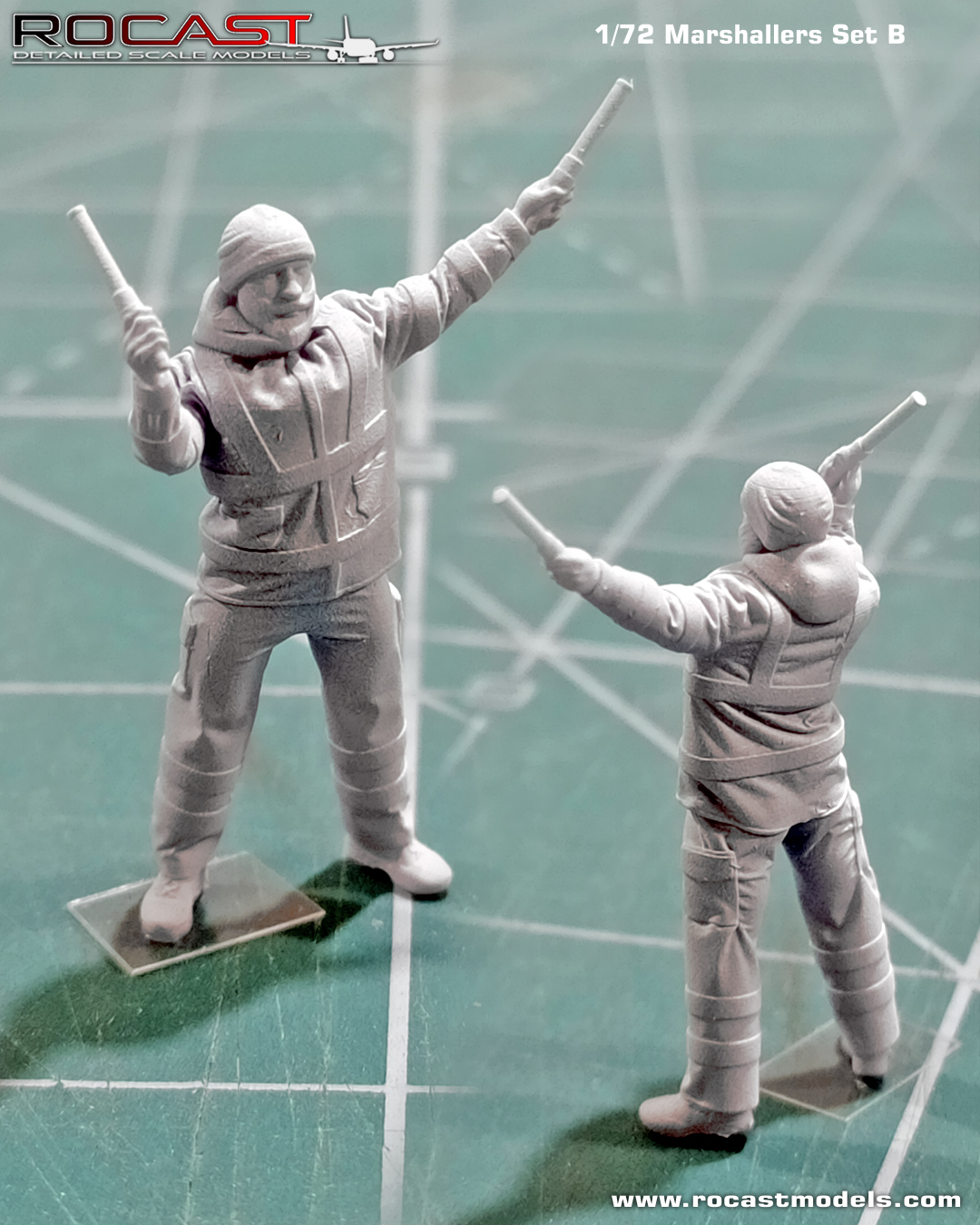

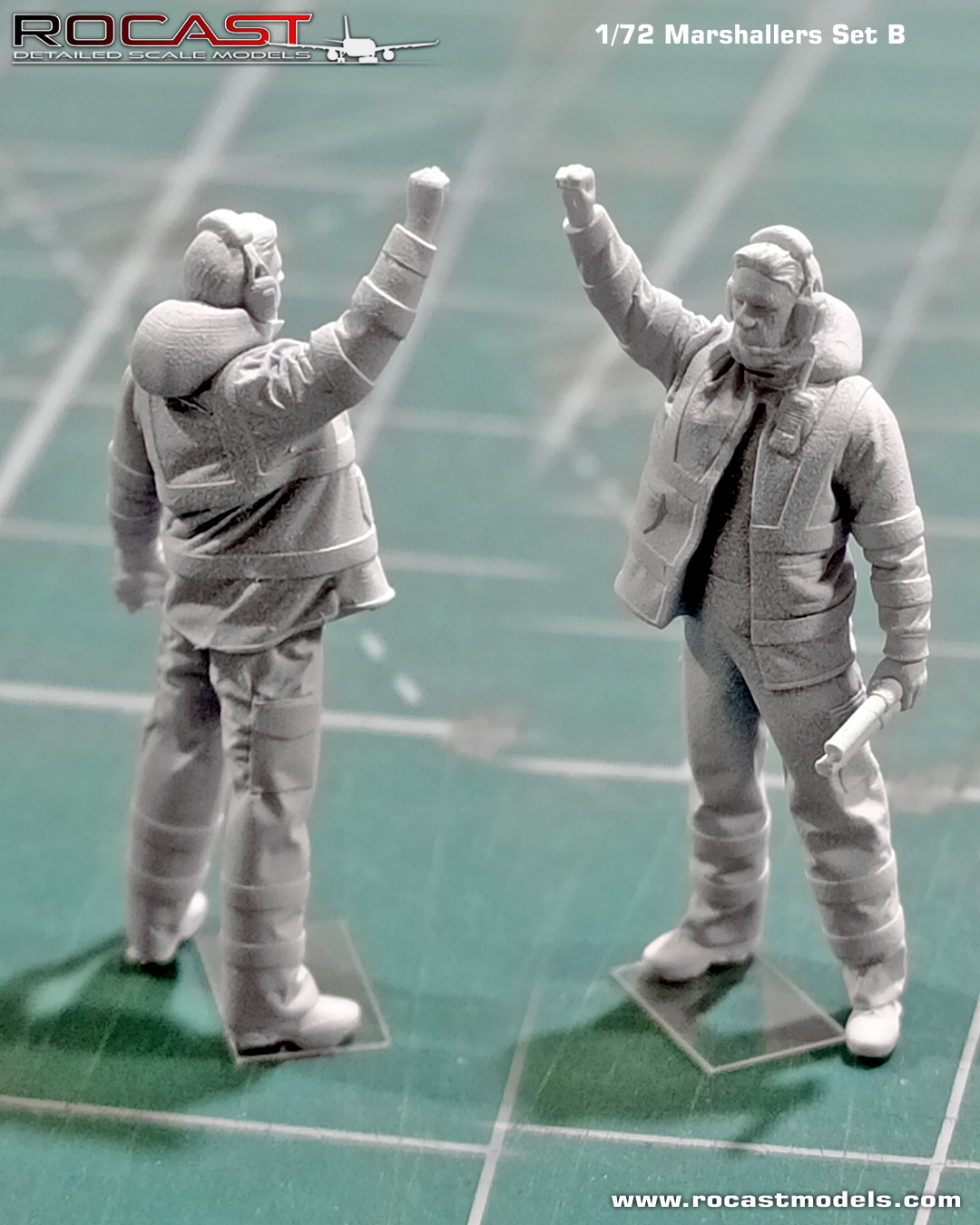

My work does not end here, but I also have been working on the new items to be released, I cannot only focus on just restocking what’s in the store but need to keep on progressing with new items. Here I present the second set of marshallers in 1/72, 1/144 and 1/200 scales. I do not want to enter into details, but this set was more difficult to make than the previous one, especially the open jacket version or the hoodie one (for which the 1/72 version had a little accident and is missing in the pictures).

I wanted to say that the fact that I do not write updates very often these days does not mean I am doing nothing, quite the contrary, I rather stay focused on working and then bring something to share in an update. I already started working on the third set of figures, this one will be used for a different scenario, so I hope to present photos soon.

Photos below show the 1/200 scale, keep in mind those figures are just about 8mm tall, and also keep in mind my camera cannot take better pictures at this size.

Photos below show the 1/144 set, these figures have sharper details than my camera can display:

Next are the 1/72 scale figures, around 25mm tall, this scale is already something our eyes can see better:

I will have to fix the back side bottom of the jacket for this figure.

To sum up on the work being done so far:

– Still in the molding stages with the 787, no issues, simply it takes more time than one initially thought.

– The set A and B for the marshallers have been completed in the three scales, pending illustrations, production and packaging.

– The new dollies and AAK containers are completed for the 1/144 scale, currently “porting” them to 1/72 and 1/200, instructions and packaging still pending.

– AKE “Wasp” dolly to be prepared for final test printing in 1/144, port to 1/200 and 1/72 pending.

– AKE containers to be redesigned and produced in 1/144, 1/200 and 1/72 scales.

– The new GSE models (catering and AST-1F pushback) are progressing as I have learned about the transparent cabins, but I am also pushing forward the revised versions of the FMC15i and stairs truck model, pending as well to restock the “old” GSE items at the shop which are more “on demand” kind of products.

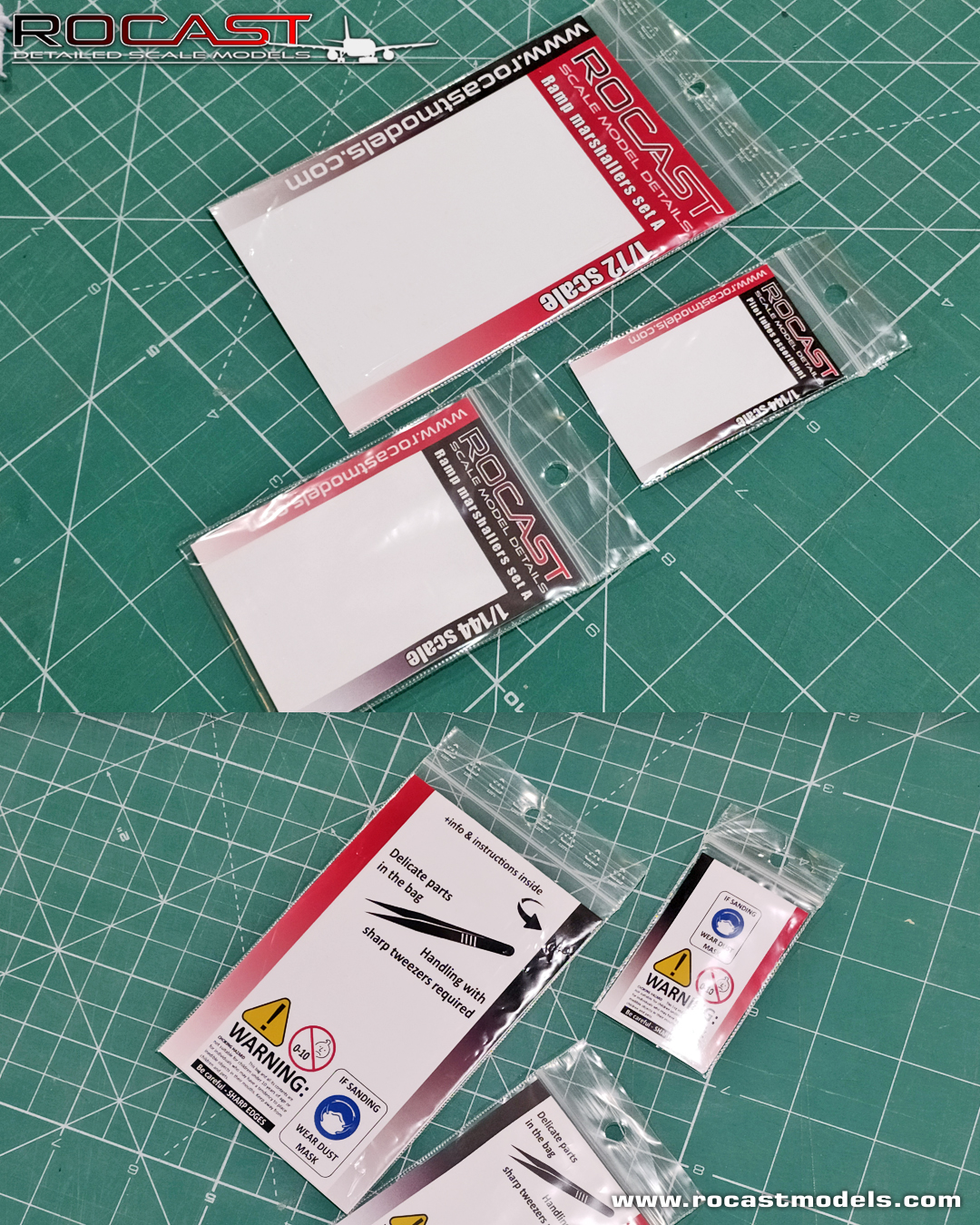

Lastly, I also have been redesigning packaging visuals. I decided not to use the color flap on the bags anymore as once they are detached from the staples and the bag is opened, the bag loses its product identification, so I have taken the liberty to make a new packaging adding certain warning labels that I thought were not necessary, but sometimes realism require of small details that the modeler need to be careful with and I feel the need to remember this on the packaging. Additionally, the bagged items that include instructions will have the illustrations within the packaging itself and/or with additional paper, paper that now has higher quality and smoothness.

I am also planning to create a video for each specific (new) item regarding the base supports removal so that this can guide and show how to separate the parts from their printed supports, therefore making the instructions more immersive and comprehensive.

There is always things going on, I am very busy at the moment trying to reach at everything, I am also trying to make my workplace a better place so that I can keep up with the materials and tools that I use or will be using on a daily basis.

My eagerness to have those projects completed and to keep creating new things has not diminished one single bit, only time is always the issue, so I will keep doing my best and hopefully bring to you all a bigger update especially on the 787 soon.

Best wishes,

Guillem