Hello everybody,

It’s been quite some time since my last update, to be honest I was looking to have something finished to share prior writing another update, but since progress on the new stuff seems to be taking some time, I decided to write a quick update.

First I want to say that I am delaying the restocking dates of the various GSE items one week, the main reason for this is that I am currently at a very crucial moment with both the 1/144 cargo loader and the 787 galley/cockpit sets. A lot of time is needed for correcting, adjusting and finishing those items (basically for the cargo loader), so I want to arrive at December (at least) with these two items’s units being produced, I am preparing stock of various GSE in between tests.

Temperatures are dropping, these changes are crucial in resin, differently than the polyurethane resin which is harder to work with on summer, thus I have to warm up the room and make some adjustments to some of the files for them to be done properly, again all of this takes some time, this is the main reason why the belt loader workers are still out of stock, however, I almost finished adjusting this.

The 1/144 Commander FMC15i cargo loader was quite difficult to do, making the scissors of the model movable made things quite challenging designwise, because there are certain things you can’t possibly do it like the 1/1 model. So far I have done two test builds from which I learned a lot, specially about fittings and detail.

I am at this point doing what I hope will be the last corrections, so if everything goes well, around Thursday/Friday I should have the first finished version.

For the first time in any other GSE I previously made, I am including 0,25 mm photo etched handrails. These are twice as thick as the ones I usually include in some GSE models, so this way the handrails are represented more realistically.

The chassis is designed so that the main platform rises at the max height as per the 1/1 specifications. The double sill and the wide bridge option is something I will be making shortly after releasing the kit and will then become an extra to chose from within the product page.

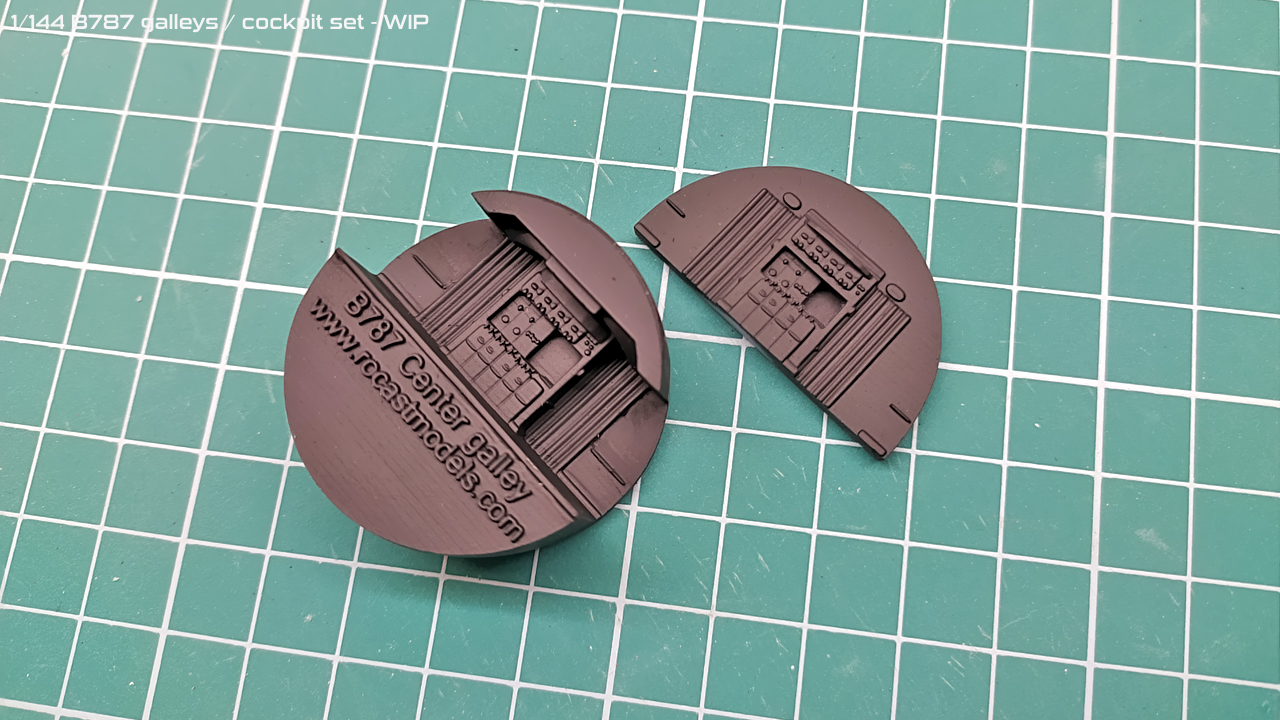

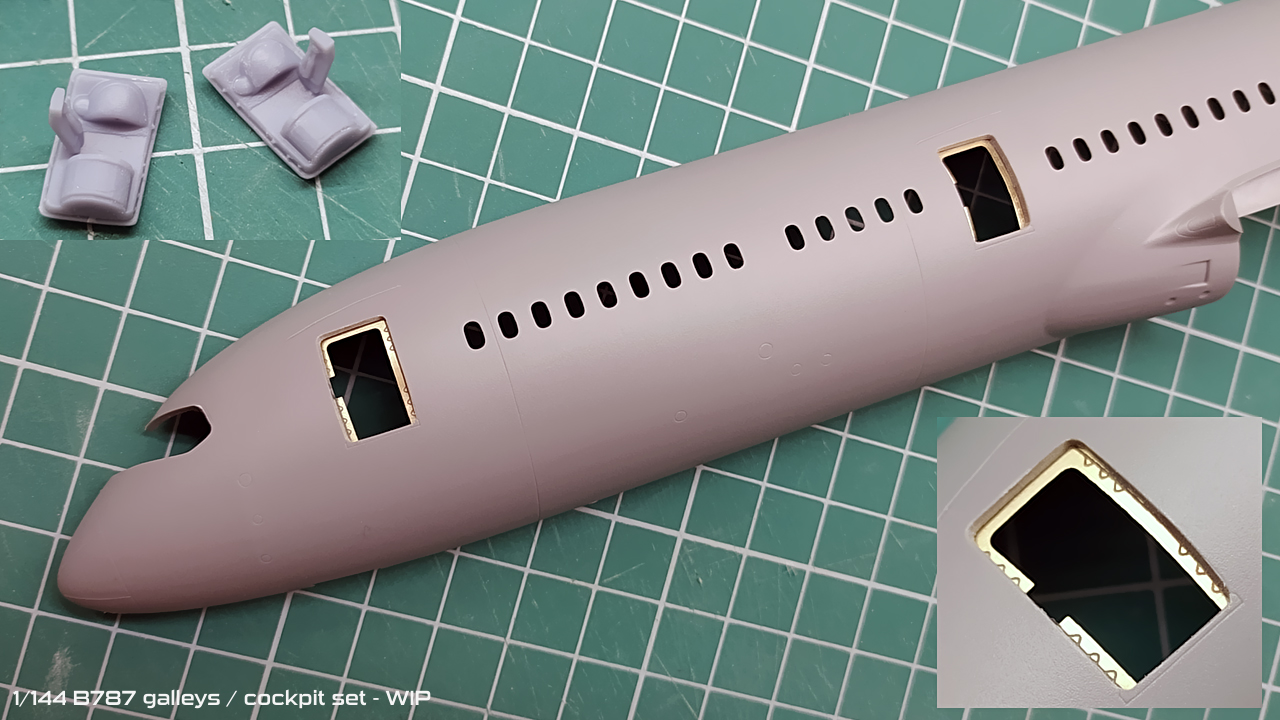

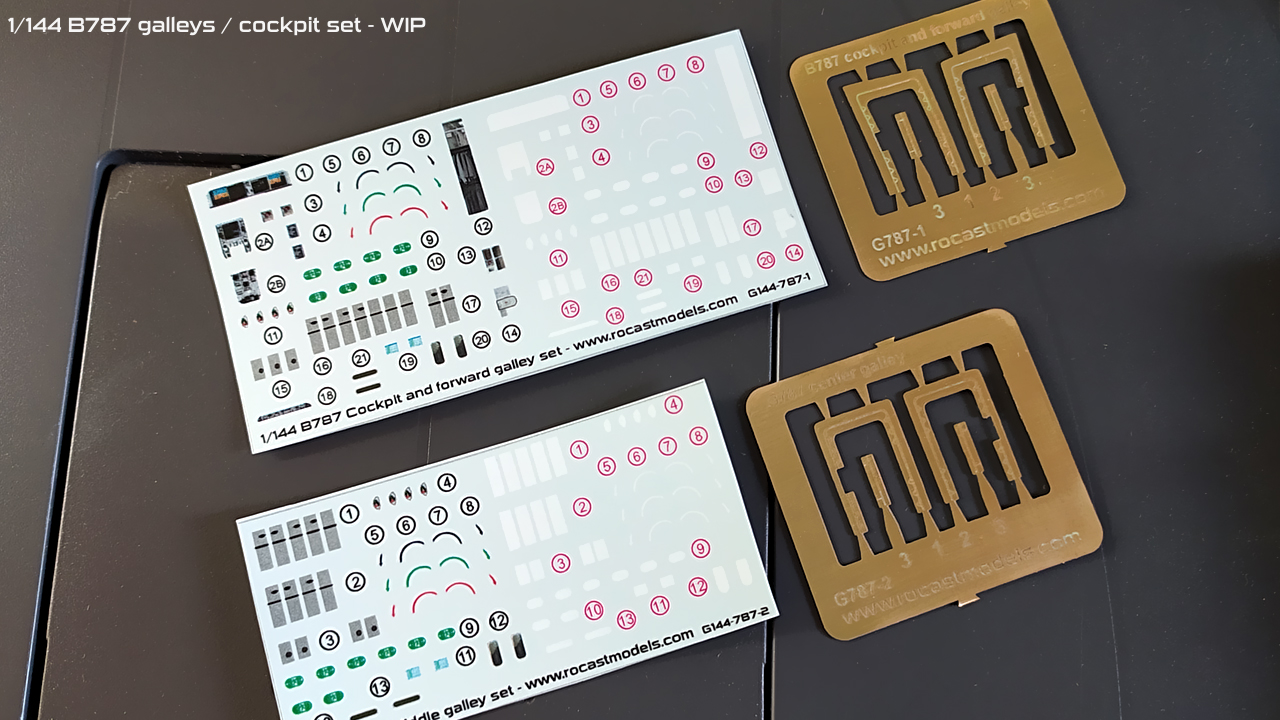

Here are some photos of the 787 galleys/cockpit sets, note that the cockpit and forward galley are not yet shown in the photos.

Each will be sold separately, meaning you will be able to get the cockpit / forward galley combo and the middle galley separately. For the B787-8 only one center galley is used, the B787-9 has two center galleys, so you can decide to either open L3 as well on the 787-9. More on how to quickly open the various doors will be explained soon.

The rear galley has been started this weekend, so chances are I may not be on time to have it before December, but I will do my best to release the three galleys at the same time.

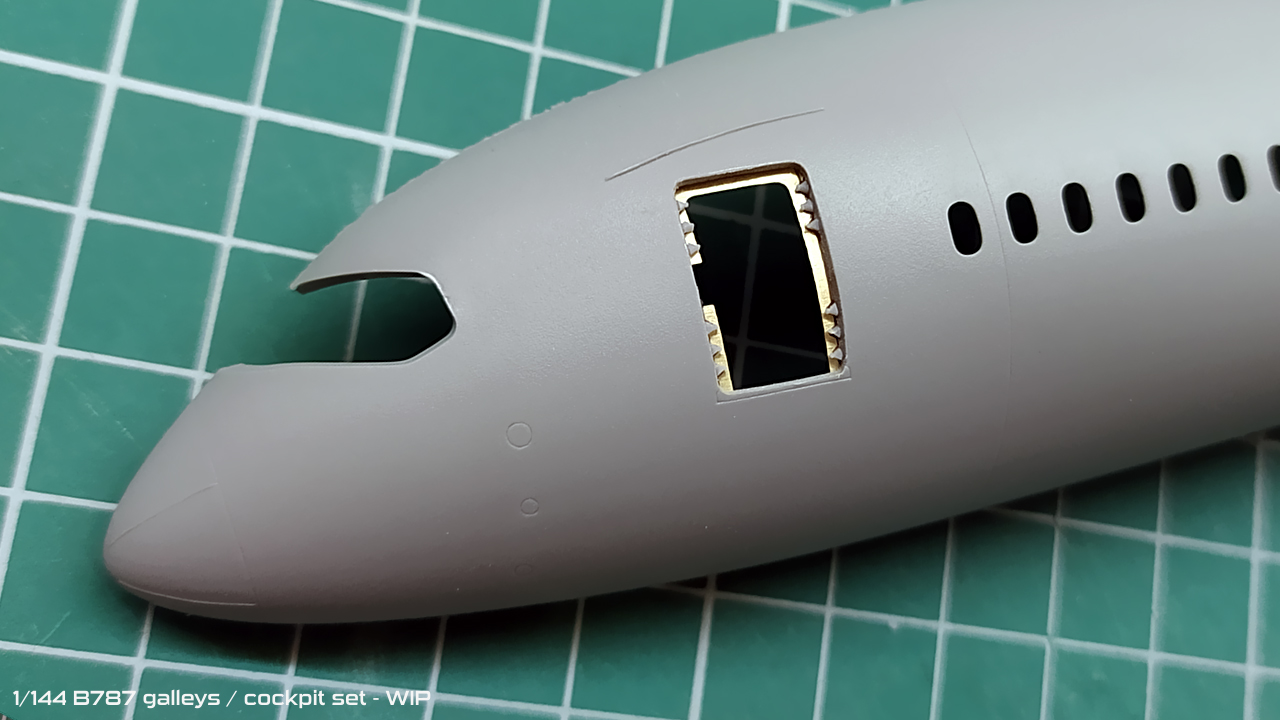

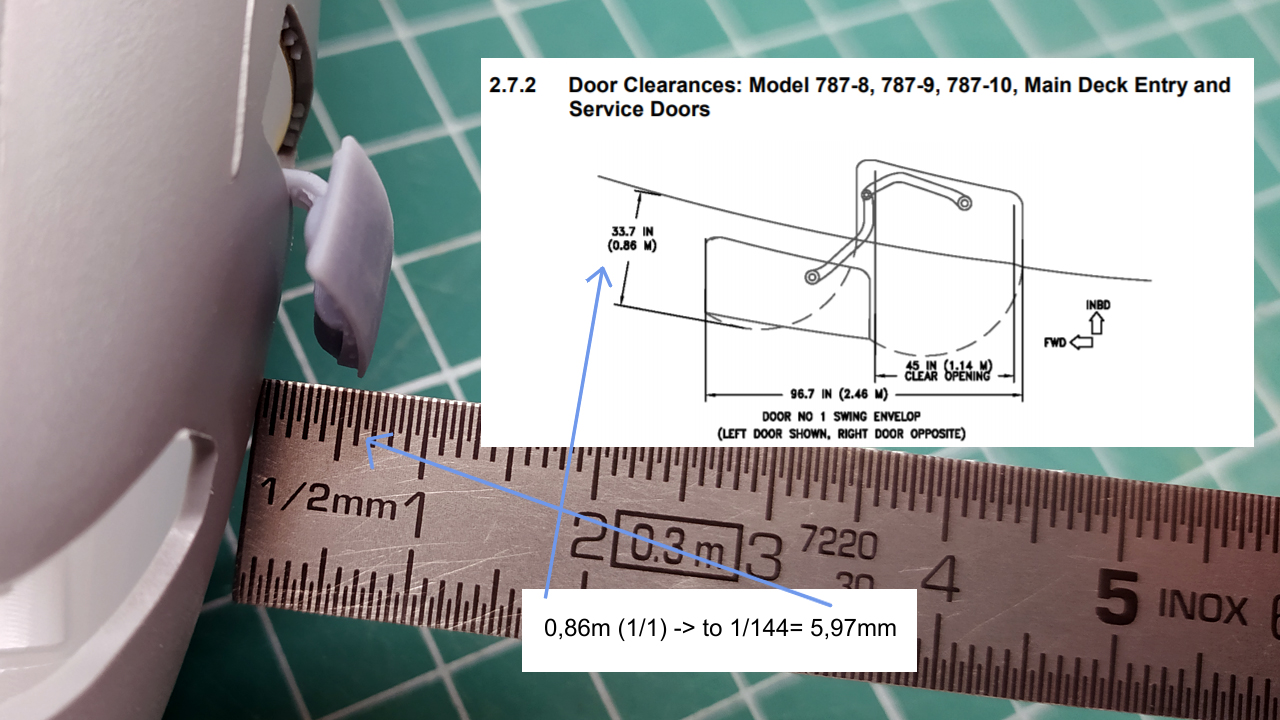

Note the PE frames placed from the inside. The width clearance matches the same as the real one, obviously converting the dimensions from 1/1 to 1/144. You can also see the different latches engraved on the frames.

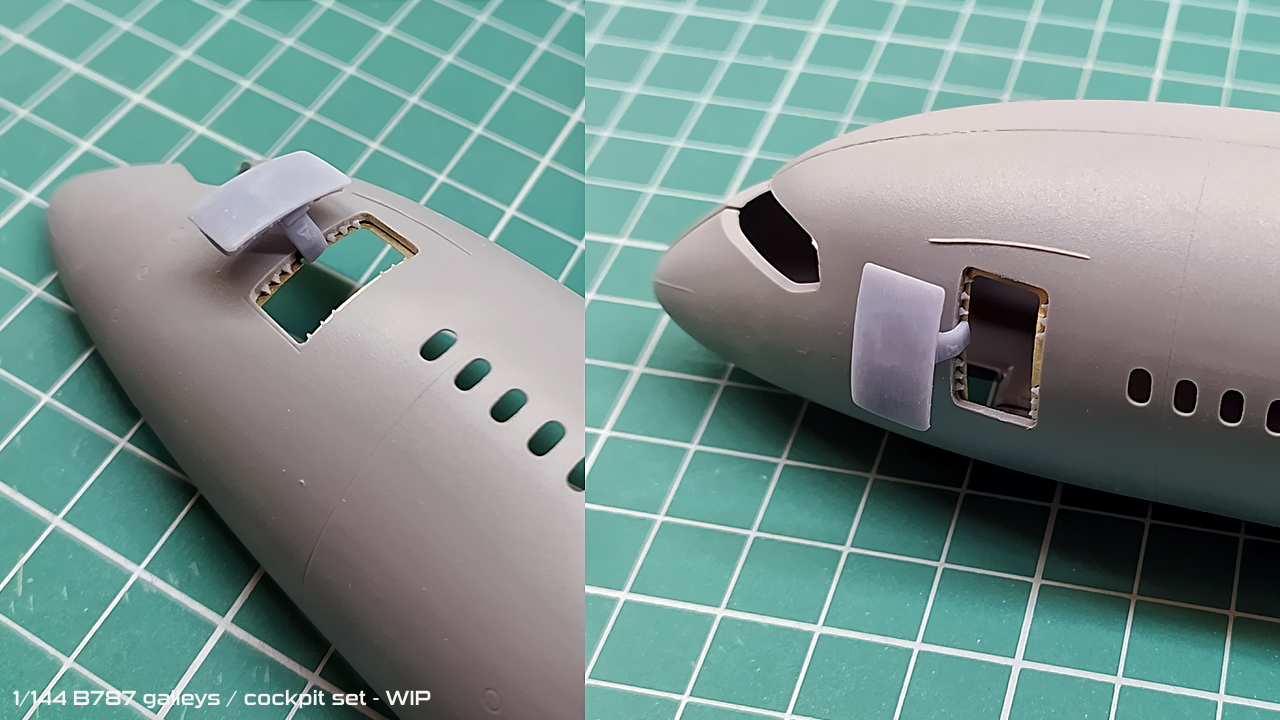

The reason to leave the latches engraved is to give you freedom to chose to leave them as they are, or to use them as a guide to put the actual resin latches on top as shown in the photo above.

These are very tiny parts, about 0,8mm wide, so I will be including plenty of spare latches in each set. These will be on customer’s behalf to cut off their supports from manufacturing, as I cannot cut the 280 latches I can produce for diverse sets, it would take me a big ammount of time which would increase the cost.

The doors have detail on the inside and outside. For producing reasons, the outside is left smooth ready for the decal, which you can use from any decal manufacturer as door dimensions are the same as the kit’s door sizes.

The door opening distance was also taken into consideration, so if placed properly, it should be very close to the actual 1/1 clearance according to the B787 airport manual.

The cockpit/forward galley set and the middle galley will both include PE and decals. The PE parts will be the door frames and the door’s step, this will be very helpful to make sure there is a nice transition between the plastic thickness and the galley floor.

There are several decals in the set, decals for the food carts, door windows (small at the top of the door and for the inside), door markings, emergency exit markings.

The cockpit also features the correspondent decals, main panel, pedestal/radios, oxygen masks, autopilot, cabinets etc.

Together with the main galley parts, PE and decals, other small resin details will be included such as: coffee machines, flight attendant seats, light control screens, emerency exit signs, interior door handles. The cockpit will include the different seats, yokes, boxes, fire extinguisher and other equipment, cabinets and cockpit door.

That is all for now, there is a lot going on here with those two items being on the final stage, so stock producing is a bit slower, I am also working on the A320/A350 decal sets, mainly testing them and doing the final steps, these will hopefully be ready at around February 2021.

I hope to be posting another update soon, at the end of the week, with more info on those projects.

Wish you all a nice week and stay safe!

Guillem